Innovative Technologies and Services

Innovative Technologies and Services

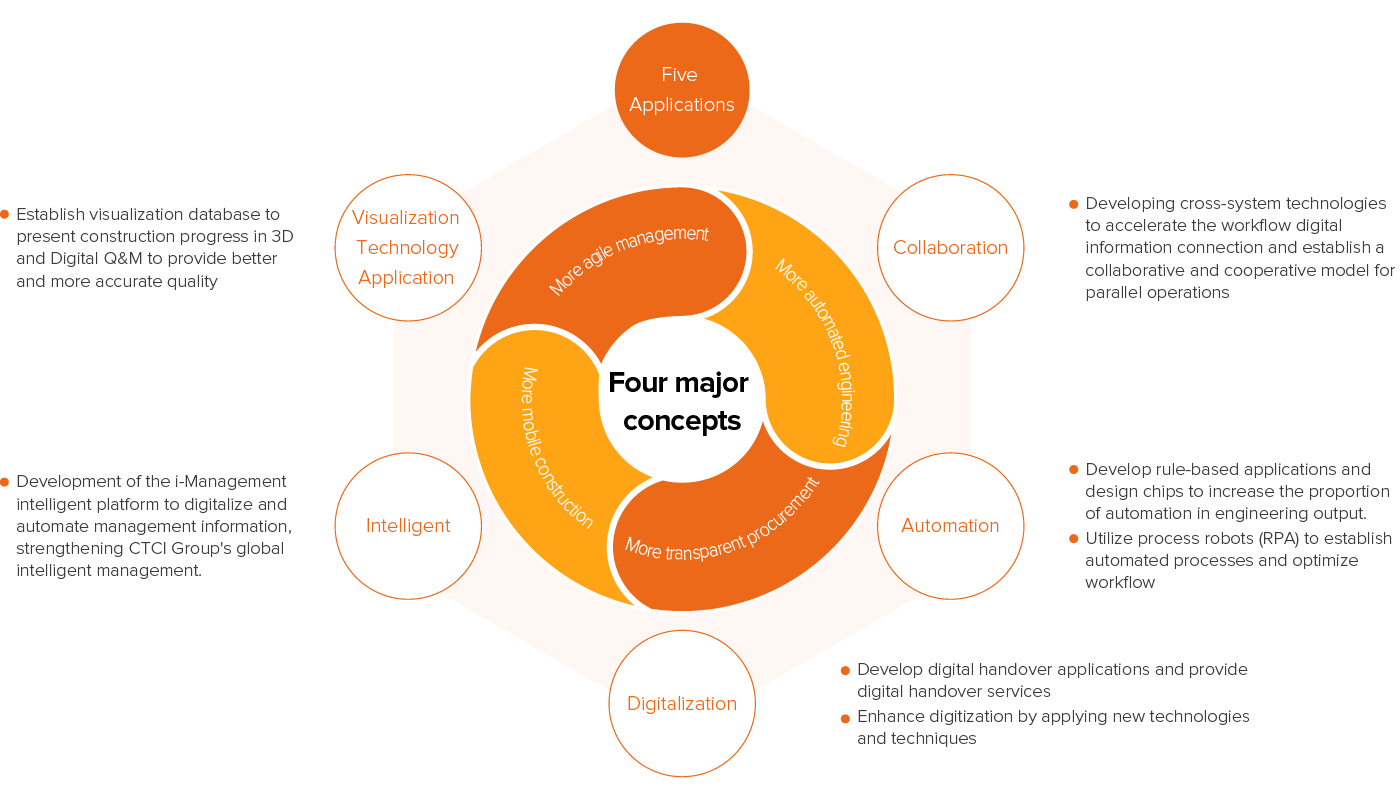

iEPC Turnkey Digital Engineering

In 2024, GRIC’s work continued to be based on four core concepts: automated engineering, transparent procurement, mobility in construction, and agile management. The Center advanced digital transformation through the development of the intelligent EPC (iEPC) platform, digital twin, and robotic applications. Through technical innovations, the digital twin embraced a cloud-native approach while capitalizing on engineering-native advantages, enabling the simultaneous creation of 3D virtual plants alongside physical construction. Looking ahead, CTCI will integrate existing intelligent systems to deliver value-added digital O&M services, streamlining data collection, analysis, and facility operations, and setting a new standard for EPC project execution.

In response to the Group’s business expansion, CTCI continues to advance technological innovation to strengthen efficiency and quality across all EPC phases. Enhanced technical capabilities not only drive improvements in safety, cost optimization, digital transformation, and carbon reduction, but also enable the delivery of "Net Zero EPC" value engineering services. In the engineering stage, CTCI is improving engineering design tools to increase automation and digitalize structured engineering data, reducing manual re-entry efforts. For procurement tasks, Robotic Process Automation (RPA) is adopted to handle repetitive tasks such as batch receiving and expediting, streamlining the procurement process. At the construction stage, new technologies enhance site digitization and efficiency, with construction progress visualized through 3D management systems to improve coordination between construction and management. In parallel, the development and application of robotics are advancing site automation. These innovations not only enable digital transformation across all EPC stages but also reinforce competitive advantages and deliver greater value engineering services. In terms of professional engineering capabilities, CTCI is strengthening its expertise to support expansion into high-tech industries and green engineering projects. Based on a comprehensive assessment of design capabilities and project execution experience, the company is enhancing design proficiency and actively pursuing net-zero opportunities. Through industry-academia collaboration and in-house design, CTCI has developed technologies in biomass biogas systems, blue ammonia, clean energy, incinerator steam turbines, bottom ash recycling systems, and high-strength steel design. These initiatives strengthen in-house design and review capabilities, establish new design guidelines and standards, and expand the share of green, low-carbon businesses. Regular workshops and training programs are held to enhance the engineers’ design skills, quality, and efficiency, ensuring the EPC team's ability to respond swiftly to market changes and deliver faster, better, more precise services to meet greater competitive demands. Details of recent R&D projects completed over the past two years can be found on pages 110 and 111 of CTCI’s 2024 Annual Report.

Technology Development

In 2024, CTCI invested approximately NT$127 million in R&D, with 64% dedicated to environmental technology development. Focus areas include real-time information dashboards, site mobility solutions, equipment information integration, desalination system research, carbon capture, hydrogen energy technologies, intelligent design, and construction simulation applications. These initiatives not only advance digital transformation across all EPC stages, but also strengthen industry competitiveness, contribute to carbon reduction, and support sustainable development. CTCI also actively engages in industry-government-academia collaboration to further expand its engineering influence.

Research and Development Prospects

Looking ahead, CTCI will uphold its commitment to professionalism and innovation, invest in proprietary R&D, and adopt advanced and emerging technologies to strengthen its technical capabilities and core competitiveness. The Company will also benchmark itself against leading global engineering firms, actively adopt innovative solutions, and integrate academic research with practical applications to drive process innovation and transformation, enabling swift responses to market changes and sustaining its competitive advantage.