Supply Chain Management

Supply Chain Management

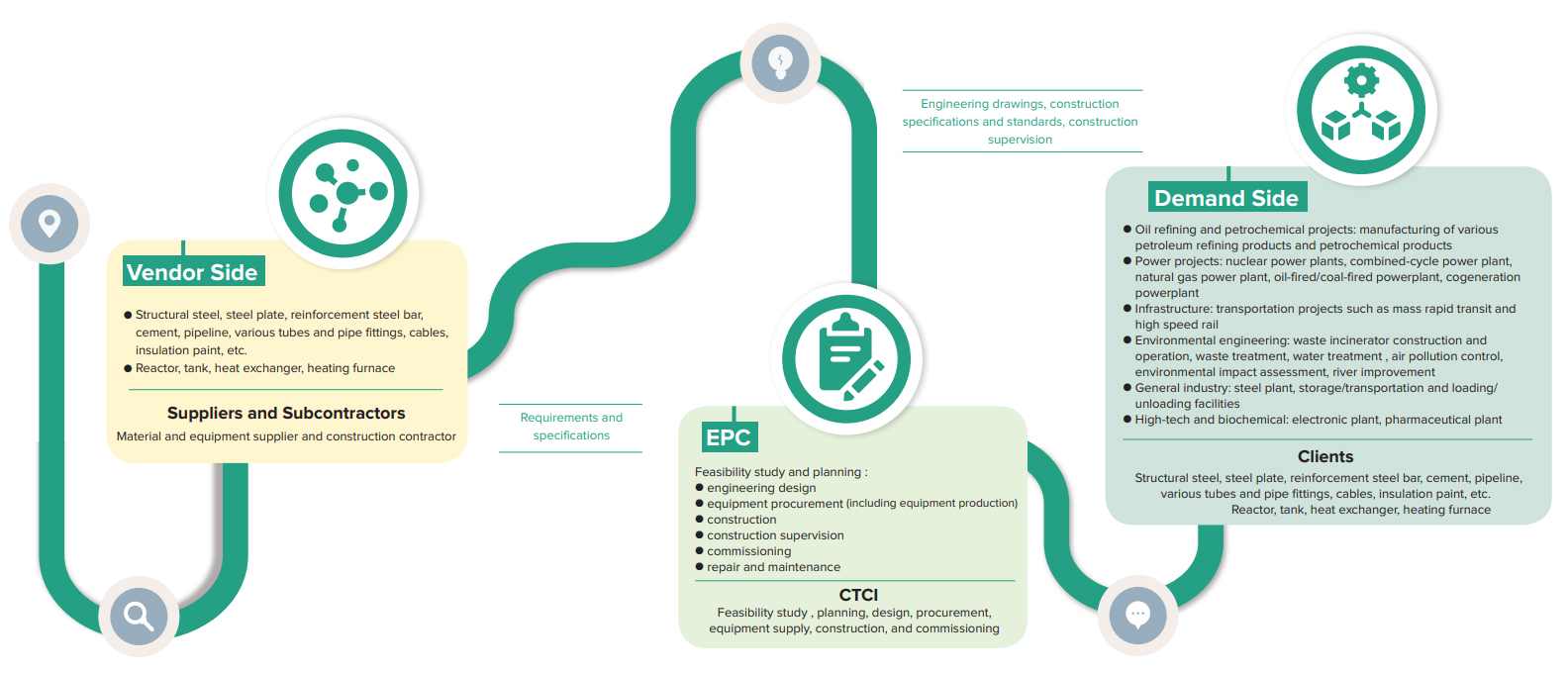

CTCI's Value Chain

CTCI Group focuses on providing EPC turnkey engineering service, with a strong presence in high-tech, hydrocarbon, petrochemical, chemical, natural gas, electricity, transportation, steel, environmental engineering and other industries. We are committed to delivering highly customized and forward-looking integrated solutions for our clients. Throughout the execution of each project, we try to understand our client needs as best as we could, while ensuring every aspect—including materials, equipment supply, construction standards, and specifications—is in alignment with global best practices, so as to optimize project quality, schedule, and performance. As the international construction industry progresses towards digital transformation and sustainable development, the demand for green buildings, smart manufacturing, and low-carbon operations is steadily increasing. CTCI actively responds to this trend by utilizing iEPC technology, introducing data-driven decision-making mechanisms, improving engineering efficiency, and incorporating energy-saving, carbon-reducing, circular economy, and environmentally friendly strategies throughout the design, procurement, and construction phases. As a leader in international engineering technology, CTCI not only focuses on technological innovation but also integrates ESG goals into the core of its business operations. We are dedicated to creating efficient, safe, and sustainable solutions for our clients through digitalization, intelligence, and green engineering technologies.

Suppliers Overview

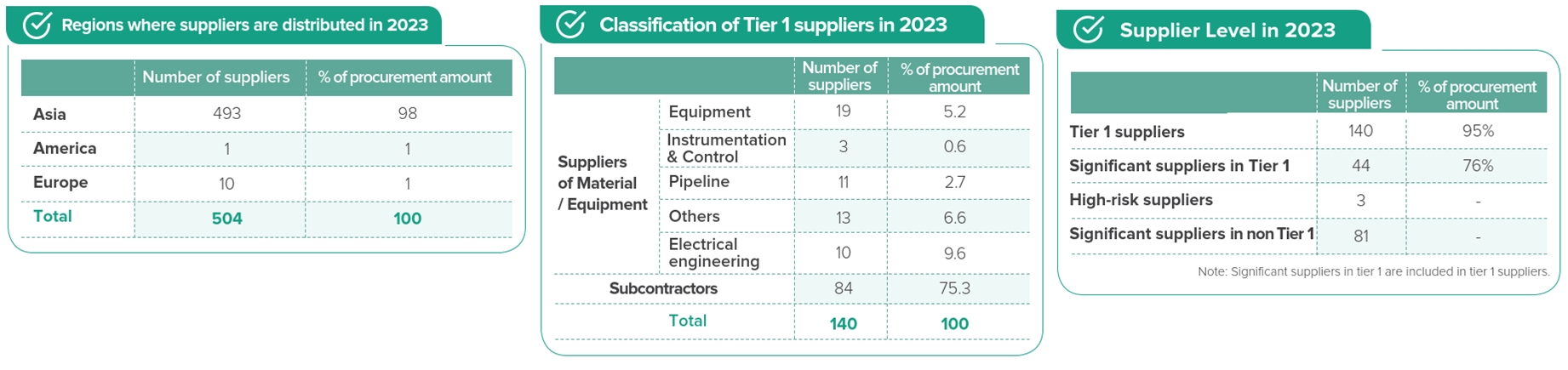

As a global EPC group, CTCI serves customers across the world and spans a wide range of industries, resulting in a complex supplier network. To efficiently manage our extensive and intricate supply chain, CTCI has established a systematic management framework. We categorize suppliers into six main types: service providers, equipment, instrumentation, piping, electrical, and others, including service-oriented subcontractors. Suppliers are further classified based on their annual transaction amount to progressively enhance the ESG performance of the supply chain. An additional classification is based on transaction value, with "Tier 1 suppliers" defined as those comprising the top 95% of cumulative annual transaction amount. Suppliers with annual transaction volumes exceeding US$3 million or those identified as high-risk (see Note 1) are designated as "significant Tier 1 suppliers" and are subject to focused management. To mitigate risks across the entire supply chain, CTCI also oversees suppliers outside the significant Tier 1 group (known as significant non-Tier 1 suppliers) (see Note 2) and require significant Tier 1 suppliers to manage the sustainability risks of their own suppliers. If high-risk conditions are identified, CTCI would conduct on-site assessments for significant non-Tier 1 suppliers. Note1: A high-risk supplier is defined as the supplier whose score in the Sustainability Risk Self-Assessment Questionnaire (SAQ) is below 50, placing it within the bottom 5% among all suppliers. Note2: A significant non-Tier 1 supplier is defined as the supplier which is among the top five suppliers of significant Tier 1 suppliers by transaction amount.

Supply Chain Sustainable Development Policy

CTCI attaches great importance to the partnership with its suppliers, and expects all suppliers to commit to sustainable development. The Company has formulated a supply chain sustainable development policy, which serves as guidance for the suppliers. The policy covers aspects such as basic construction safety integrity management, employee rights, climate, and ecological actions.

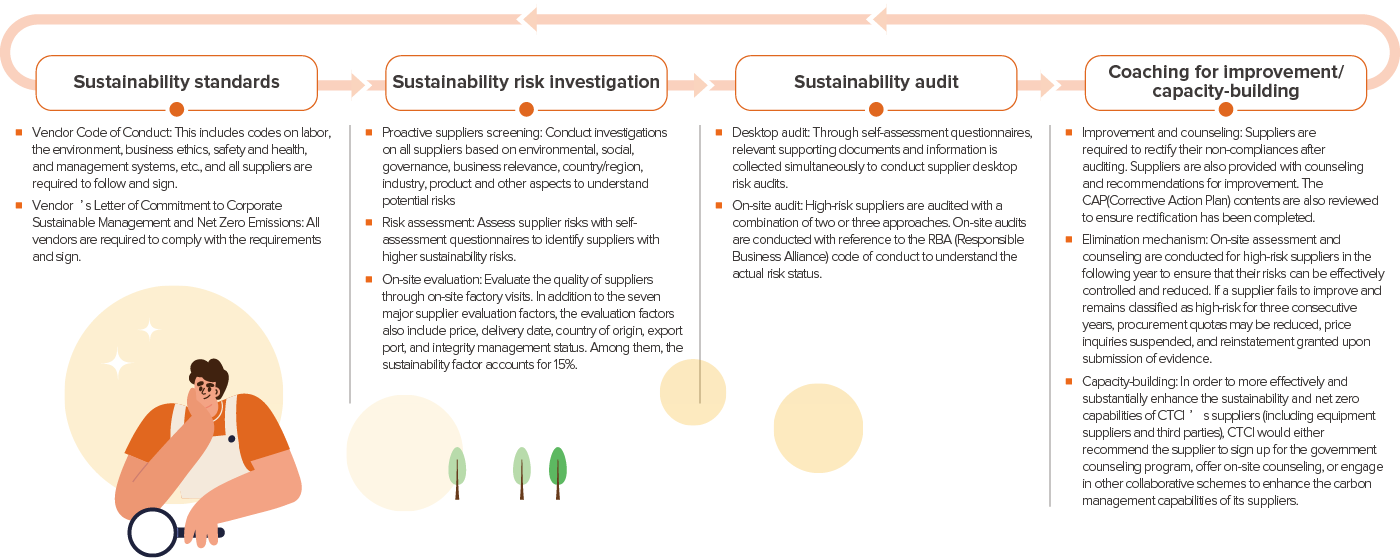

Sustainability Standards

To ensure that our suppliers align with CTCI’s sustainability goals, we have developed the CTCI Vendor Code of Conduct and Vendor’s Letter of Commitment to Corporate Sustainable Management and Net Zero Emissions, based on international sustainability trends, related initiatives, and regulatory requirements such as UN Global Compact, Universal Declaration of Human Rights, Responsible Business Alliance Code of Conduct. These two documents apply to all suppliers (including new suppliers) as well as their subsidiaries, affiliates and contractors and any providers of goods or services to CTCI. They cover all aspects including labor practices, environment, business ethics, safety and health, and management systems. CTCI expects its suppliers to further communicate with their own suppliers about the relevant sustainability requirements, monitor their compliance, and work together with CTCI to promote the sustainable development of the entire industry chain. By the end of 2024, 100% of CTCI’s suppliers had signed the Vendor Code of Conduct. In addition, since 2016, all new suppliers have been required to sign the Vendor’s Letter of Commitment to Corporate Sustainable Management and Net Zero Emissions, achieving a 100% signing rate—underscoring CTCI’s shared commitment to driving sustainability throughout the supply chain.

Sustainability Risk Investigation

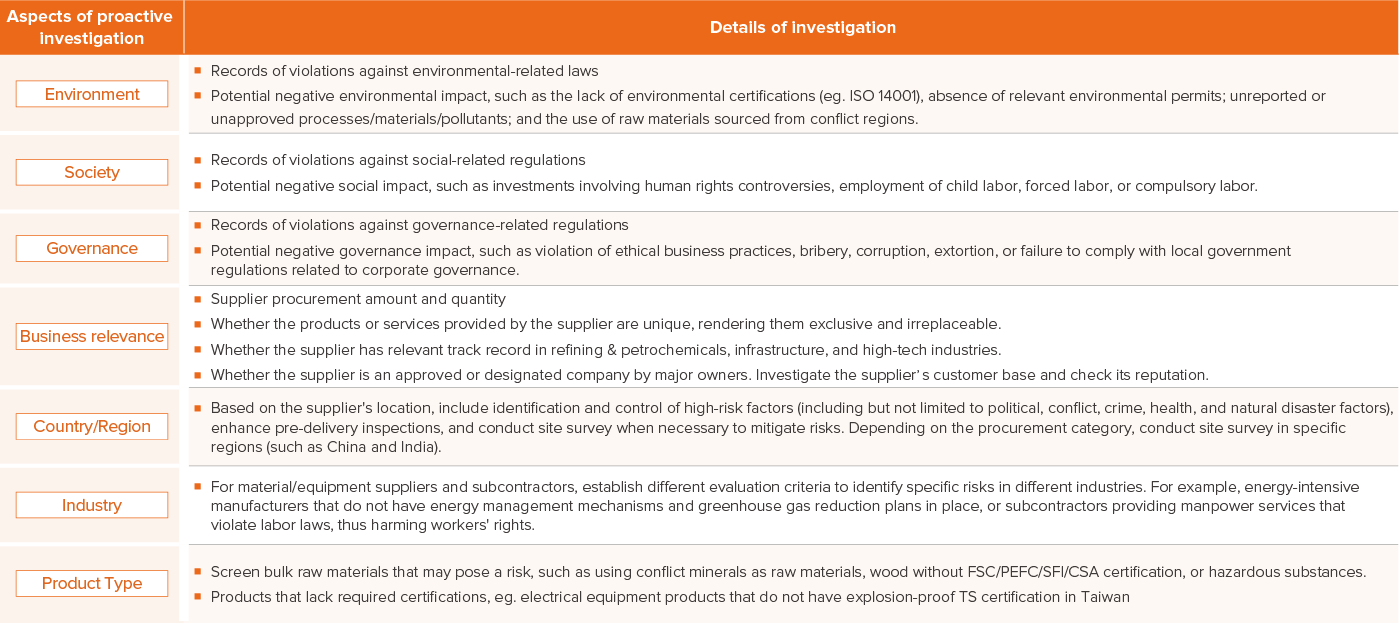

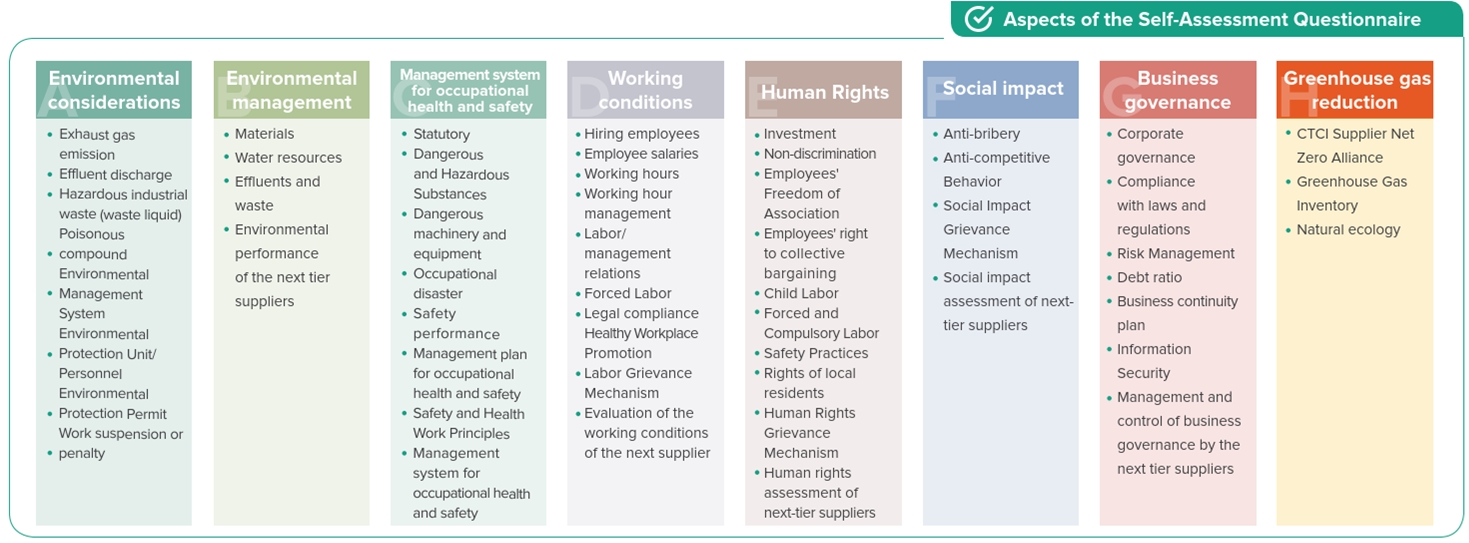

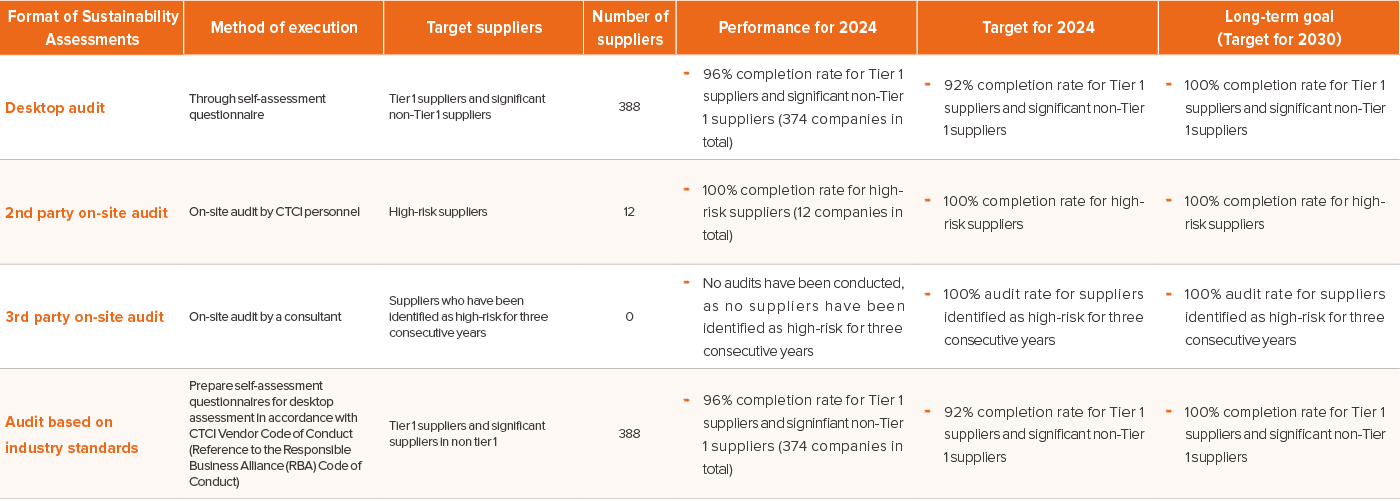

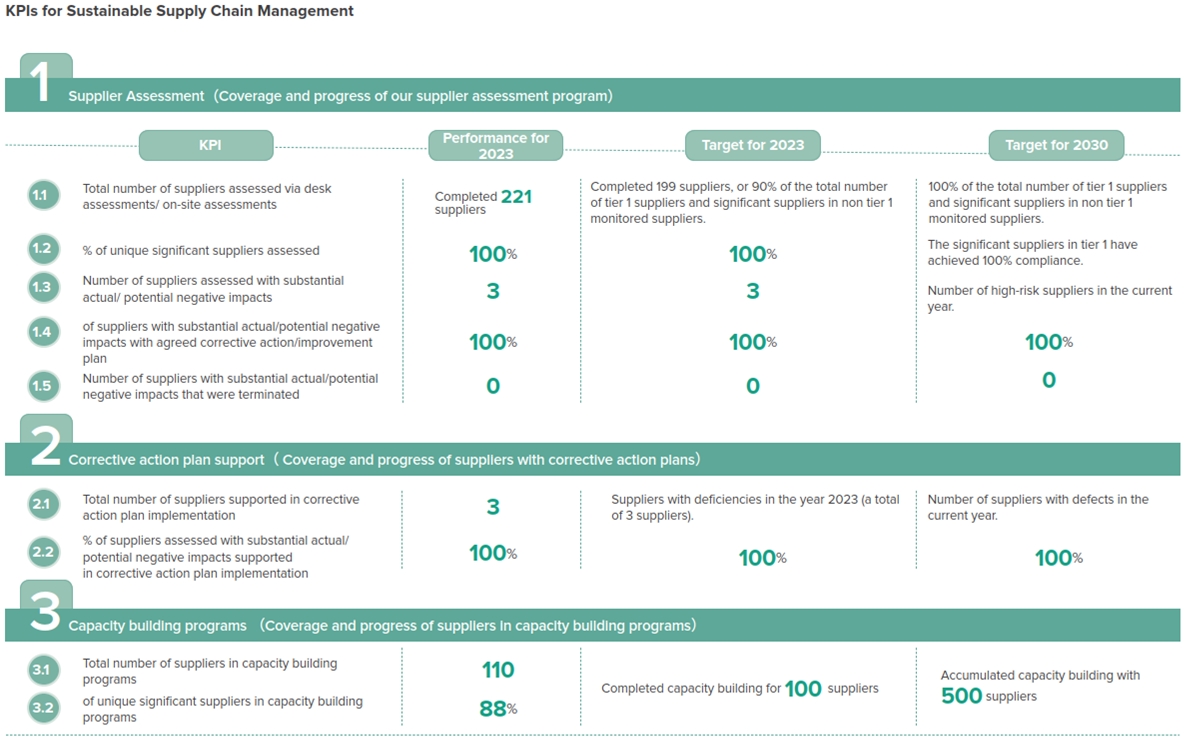

To assess the sustainability risk profile of suppliers and the implementation of their sustainability practices, CTCI has adopted a two-stage risk assessment mechanism, which includes proactive investigations and the sustainability risk self-assessment questionnaire survey to comprehensively identify potential risks. For suppliers identified as having higher risk based on the assessment results, CTCI would conduct further assessments and provide guidance for improvement, helping them enhance their management capabilities, reduce risks, and strengthen the overall resilience of the supply chain.

Results of Supplier Assessment

CTCI conducts proactive investigations using various screening dimensions and methods. The screening dimensions include business relevance and potential negative impacts on environmental, social, and governance aspects. The screening methods take into account of country-specific risks, industry-specific risks, and product-specific risks. By evaluating these dimensions, CTCI aims to identify potential supplier risks at the earliest stage and lay the foundation for subsequent management and risk control.

Reward and Elimination Mechanism

To ensure the stability and reliability of the supply chain, CTCI has established a dual mechanism of reward and elimination to incentivize suppliers to enhance their sustainability performance. We prioritize the selection of suppliers with strong sustainability performance during the bid evaluation stage, particularly when multiple bids are closely priced. Outstanding suppliers are publicly recognized at regular supplier meetings, not only enhancing their market reputation but also setting a positive example for others. On the other hand, an elimination mechanism is in place to ensure that the quality and ethical standards of products and services are upheld. Suppliers that are found to be involved in misconduct such as bribery, bid abandonment, collusion, or coercion are immediately disqualified and terminated from cooperation. For those identified as high-risk suppliers, CTCI would conduct on-site audits and provide coaching to help them improve management practices and mitigate risks. If a supplier fails to make improvements and remains in the high-risk category for three consecutive years, CTCI will reduce procurement volume or suspend quotations until concrete evidence of improvement is provided. In 2024, no suppliers were eliminated. Through this parallel system of rewards and penalties, CTCI aims to encourage suppliers to prioritize sustainability, effectively manage risks, and ensure the long-term resilience and sustainable operation of the supply chain.

Capacity Building

CTCI Supplier Meeting and Outstanding Supplier Recognition

CTCI holds a biennial supplier meeting to strengthen collaboration and communication with domestic and international vendors. The 2025 Supplier Meeting was held on March 7 and expanded its scope to cover the Group’s entire supply chain. This hybrid event welcomed 105 suppliers from 11 countries (87 domestic and 18 international), with 181 participants attending in person and another 152 joining virtually. Themed "United for a Sustainable and Prosperous Future," the meeting focused on enhancing supply chain resilience and driving sustainable development. CTCI shared its sustainability and net-zero strategies and goals. A diverse agenda addressed how to tackle current environmental challenges and ensure the long-term stable development of the supply chain. Supplier representatives were also invited to present practical experiences in ESG implementation, providing valuable insights and inspiration to fellow attendees. To further leverage group synergies, the meeting featured a special presentation by CTCI subsidiary CTCI Advanced Systems Inc., which introduced its “Mr. Energy” platform. This platform is a system designed to assist suppliers with energy management and greenhouse gas emission inventories, thereby supporting supply chain partners in achieving their carbon reduction goals.

Sustainable Engineering Forum and Environmental Action

A Sustainable Future: AI x Nature-Based Solutions x Sustainable Talent

On December 6, CTCI Group and the CTCI Education Foundation jointly held the 2024 Sustainable Engineering Forum, themed “A Sustainable Future: AI × Nature-Based Solutions × Sustainable Talent.” CTCI Group Chairman John Yu presented the Company's sustainable initiatives and invited several scholars and experts from the engineering field to share their practical experiences, including insights from COP29, applications of artificial intelligence, natural governance, and talent development. The forum aimed to foster the exchange of real-world case studies and enhance interaction around social impact. The event attracted a total of 244 offline attendees and 176 online participants.

CTCI Green Power for Life: Protecting Wetland Biodiversity

On October 12, CTCI collaborated with value chain partners, including Ta Ya Electric Wire and Cable Co., Ltd. and Fu Tsu Construction Co., Ltd., to participate in the annual environmental initiative titled "CTCI Green Power for Life: Protecting Wetland Biodiversity," held at Guandu Nature Park. The event featured a variety of activities, including an introduction of wetland ecosystems, removal of tall grasses and Mikania micrantha (mile-a-minute weed), and a family-friendly creative DIY workshop. The initiative aimed to protect the Tamsui River and its surrounding wetlands while contributing to the promotion of biodiversity.

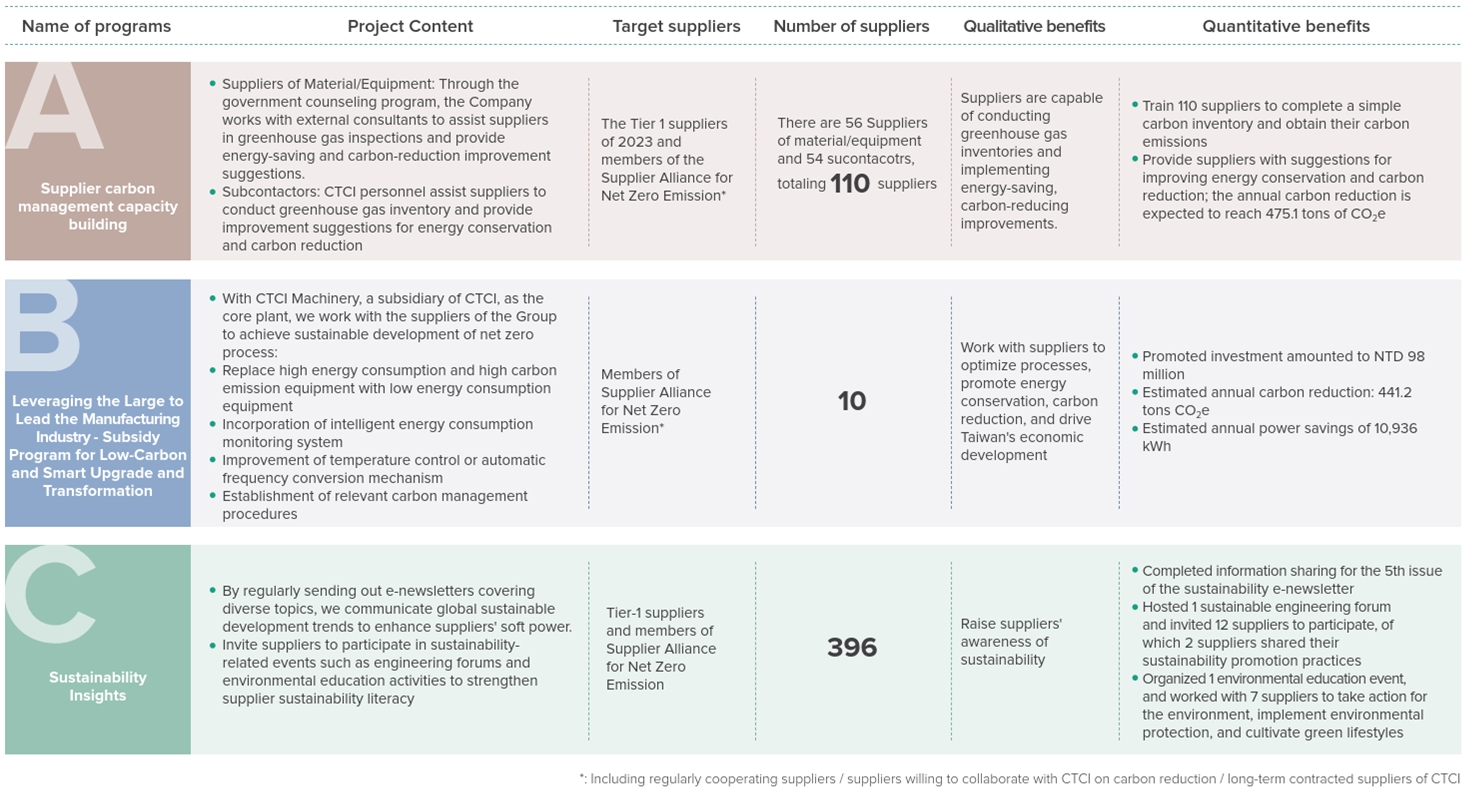

Capacity building programs

To enhance suppliers' ESG performance, CTCI provides professional resources and training to help suppliers build sustainability capabilities, with all collaborative projects lasting over six months. In addition to the domestic supply chain, CTCI's subsidiaries are also required to promote the sustainability of the global supply chain in accordance with the Group's Supply Chain Sustainability Management policy, to drive sustainability across the global supply chain and expand the influence on the entire value chain. This ensures compliance with sustainability requirements and fosters continuous improvement.

Green Transportation and Local Procurement

When selecting transportation contractors, CTCI prioritizes the ones who shares its vision. CTCI prefers those who have passed ISO 14001 Environmental Management Certification. To reduce the environmental impact from transportation, CTCI actively adopts strategies of green transportation. To reduce transportation distance and energy consumption, the Company prioritizes local procurement and flexibly adjusts the proportion of procurement and contracting according to project locations and specifications in different phases of the projects every year. In 2024, CTCI's main projects were concentrated in Taiwan, Vietnam, and Qatar, with procurement proportions of 99.85%, 0.07%, and 0.05%, respectively. Taiwan's local procurement proportion reached 91.0% in 2024, indicating CTCI’s commitments to promoting local economic development and reducing carbon footprint. If local procurement is not possible, CTCI would prioritize low-carbon, low-sulfur and low-pollution forms of transportation, such as prioritizing sea transport over air transport for energy conservation, while requiring forwarders to place orders through shipping companies that adhere to the "2023 IMO Strategy on Reduction of GHG Emissions from Ships," which imposes a minimum carbon emissions reduction target of 20% by 2030 and 70% by 2040, as well as requires the use of ships powered by low-sulfur fuel oil by 2020 in the purchase order. In terms of sea transportation, since newly built ships have better fuel efficiency, CTCI uses ships that are aged no more than 15 years. During LCL or consolidation, cargoes with close delivery locations or shipment periods can be combined into a single batch for transportation if the project schedule allows.